Due to the instability of plastic shells and materials, as well as the risk of electrostatic charge accumulation, most explosion-proof products adopt metal shells or metal components to reduce the occurrence rate of explosion risks. However, the application of metal shells and metal components also needs to consider the characteristics of the metal. For example, aluminum, magnesium, and other highly active materials are not suitable for direct use on the shell. The more common materials are cast aluminum, cast iron, cast steel, stainless steel, etc. In Chapter 8 of GB/T 3836.1-2021 Explosive Atmospheres Part 1: General Requirements for Equipment, there are also specific basic requirements for metal enclosures and metal components of enclosures.

8 Metal shells and metal components of shells

8.1 Material Composition

The materials of the shell or shell components should be specified in the documents required in Chapter 24.

Note 1: The document does not require experimental verification of the chemical composition of the material.

Note 2: The paint or coating applied to the metal shell is a non-metallic component of the shell, and the requirements of GB/T 3836.7.4 "Electrostatic Charge on External Non Metallic Materials" apply.

Note 3: Zinc and zinc alloys containing 80% or more zinc are prone to rapid deterioration (especially in terms of tensile strength), especially in warm and humid air. Zinc is also considered more active than other metals. Some explosion-proof types do not allow the use of zinc in the casing.

8.2 Class I equipment

The total content (mass fraction) of the shell material for manufacturing Class I EPL Ma or Mb equipment should not exceed:

15% aluminum, magnesium, titanium, and zirconium, with magnesium, titanium, and zirconium not exceeding 7.5%.

The above requirements do not apply to Class I portable measuring equipment, but the equipment should be marked with the symbol "X" according to the requirements of 29.3e), and special precautions should be indicated during storage, transportation, and use under special conditions of use.

8.3 Class II equipment

The total content (mass fraction) of Class II equipment shell materials manufactured for different equipment protection levels should not exceed:

For EPL Ga: 10% aluminum, magnesium, titanium, and zirconium, with magnesium, titanium, and zirconium not exceeding 7.5%;

For EPL Gb: 7.5% magnesium, titanium, and zirconium;

For EPL Gc: There are no other requirements except that the fan, fan cover, and vent baffle should meet the requirements of EPL Gb.

If the material composition limit of the EPL Ga or Gb level equipment mentioned above is exceeded, the equipment should be marked with "X" according to the provisions of 29.3e), and the special use conditions should contain sufficient information to ensure that the user can determine whether the equipment is suitable for use under specific conditions, such as preventing ignition hazards caused by impact or friction.

8.4 Class III equipment

The total content (mass fraction) of Class III equipment shell materials manufactured for different equipment protection levels should not exceed:

For EPL Da: 7.5% magnesium, titanium, and zirconium;

For EPL Db: 7.5% magnesium, titanium, and zirconium;

For EPL Dc: There are no other requirements except that the fan, fan cover, and vent baffle should meet the requirements of EPL Db.

If the material composition limit of the EPL Da or Db level equipment mentioned above is exceeded, the equipment should be marked with "X" according to the provisions of 29.3e), and the special use conditions should contain sufficient information to ensure that the user can determine whether the equipment is suitable for use under specific conditions, such as preventing ignition hazards caused by impact or friction.

8.5 Copper alloy

If intended for use in environments containing ethylene glycol, the equipment casing and Ex component casing for external installation, if made of copper or copper alloy, shall meet the following requirements:

Coating with zinc, nickel or other coatings; or

The maximum copper content in the alloy shall not exceed 65%.

The cable entry devices, sealing components, threaded pipe joints, and insulation sleeves specified in Appendix A are not considered as shell surfaces that require coating or copper content limitations.

Note: The restriction on the use of copper in a fast environment is due to the possible formation of acetylides on the outer surface that can be ignited by friction or impact.

We can summarize from the standards that:

1. For Class I EPL Ma and EPL Mb equipment, there are clear requirements for the aluminum content of the shell metal material. And equipment with aluminum metal shells should be marked with the symbol "X" according to the requirements of 29.3e), and special precautions should be indicated during storage, transportation, and use under special conditions of use.

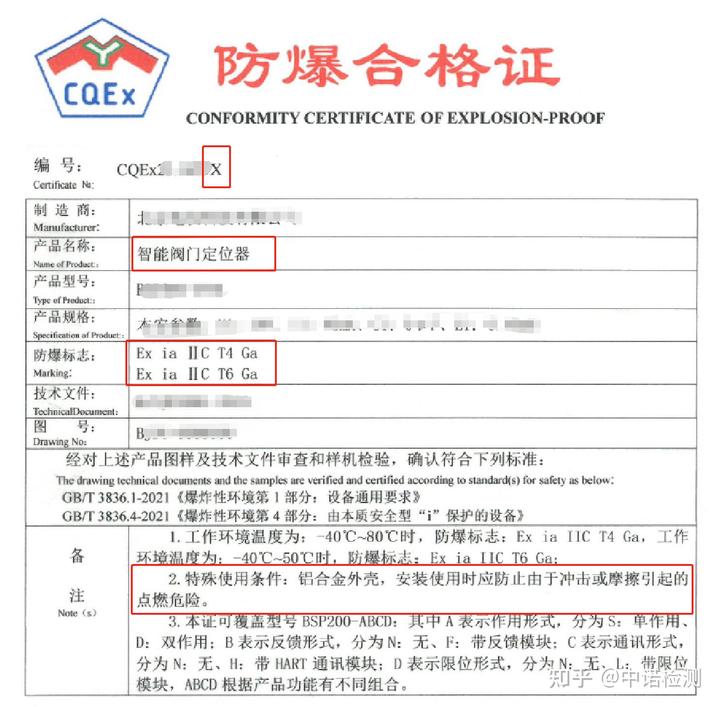

2. For Class II EPL Ga equipment, there are clear requirements for the aluminum content in the metal material of the casing. We generally do not recommend using aluminum alloy shells. If the customer's product uses an aluminum alloy shell, a material report for the metal shell must be provided, specifying the aluminum content. If the aluminum content exceeds the specified limit, there are two common solutions.

(1) The equipment must be marked with the symbol "X" in accordance with the requirements of 29.3e, and special usage conditions should contain sufficient information to ensure that users can determine whether the equipment is suitable for use under specific conditions, such as preventing ignition hazards caused by impact or friction.

(2) Reduce the protection level of the equipment, such as lowering the explosion-proof label from Ex ia IIC T4 Ga to Ex ia IIC T4 Gb.

4. Requirements for the use of copper or copper alloys in environments containing acetylene. Specific requirements have been made for the metal casing and casing metal components of equipment used in acetylene environments in GB/T 3836.1-2021 and GB/T 3836.2-2021, respectively. But according to the principle of prioritizing specific standards over general standards. The copper content in the alloy is required to not exceed 60%.

Plagiarism and reposting are prohibited on any platform!

|

||||||

|

||||||